When it comes to purchasing Bolts, you need to find the right grade of a bolt to make sure you have a solid and durable fix. Bolts are steel fasteners that come with external male threads. Their primary use is to assemble two unthreaded objects, usually with the help of a nut. If you are looking for detailed information on this topic, then this article is just for you. In this article, we will explain different grades of bolts. So, without any further ado, let’s head to the key points!

Tensile Strength of a Bolt

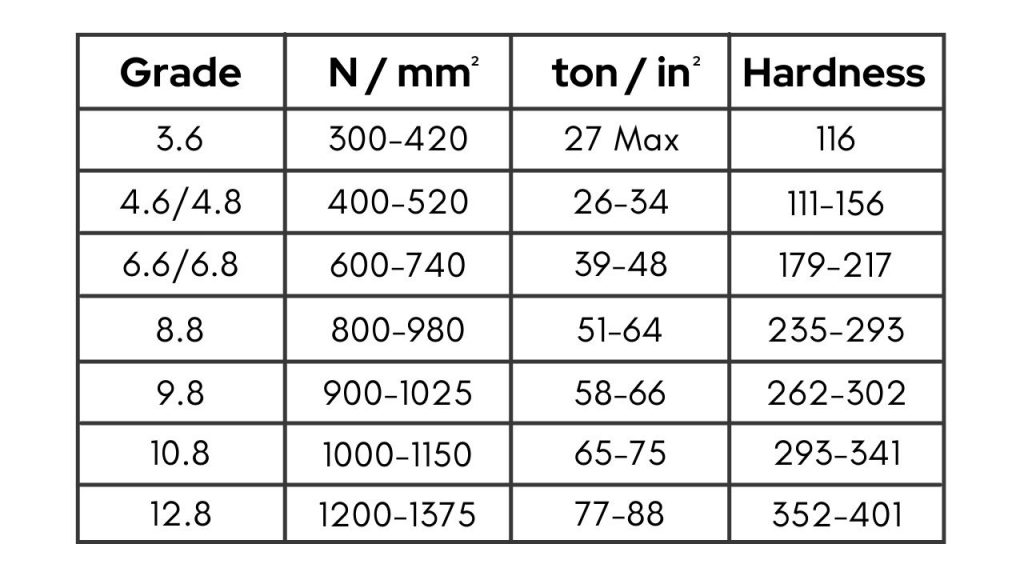

As we discussed earlier, most commonly, bolts are available in different grades. This grade often determines the tensile strength i.e., the maximum amount of stress the bolt can handle. Generally, tensile strength is the maximum load that a material can support without breaking when stretched or divided by the original cross-sectional area of the material. For bolt, it’s the amount of impact that the bolt can withstand before breaking.

There’s a wide range of bolts available in the market. The higher the tensile strength, the better the quality and its resistance to bear impact. High Tensile Fasteners are needed for high-stress applications. High tensile strength is necessary for these fasteners to hold different objects together that requires high strength.

High tensile steel is the most preferred choice for fasteners and fixings. One can easily find it in several homes and in the automotive industry.

High Tensile Bolts make your job much easier and safer when it comes to strength. Therefore, it is the right fit for guaranteed better performance and durability.

Different Grades of High Tensile Bolts:

• Grade 8.8 High Tensile – Commonly referred to as the structural grade for bolts. Grade 8.8 is one of the most common forms of high tensile material and is stocked in plain finish or zinc. It can further be plated in many other coatings. It usually requires a torque wrench for the tightening on any given product.

• Grade 10.9 Bolts – These are most commonly used in automotive applications and for bolting heavy to medium forged parts. It is made up of carbon steel or boron steel. Examples: Socket, Countersunk buttons. Its minimum Tensile Strength (MPa) is 1040 MPa 150839 psi.

• Grade 12.9 Bolts – These fasteners and fixings are for the heaviest objects that require high strength jobs. Examples: securing engines, motor casings. Its minimum Tensile Strength (MPa) is 1220 MPa 176946 psi.

• Grade 14.9 Bolts – These are the higher-end range of bolts that are used for more structural products that require the highest strength. Its minimum Tensile Strength (MPa) is 1400 MPa 203052 psi.

Regardless of their grade, all of these bolts are built to last longer. They serve their purpose seamlessly and perform optimally under severe usage. You can easily identify it via a permanent marking on its head to allow customers to further differentiate them without any complexities.

If you are looking for the right set of bolts, then there is no better place to buy than Wrights Auto Supplies. At Wrights Auto Supplies, we offer you all grades of bolts. We are the one-stop destination for all nuts-and-bolts solutions. We are one of the most trusted suppliers with over 40 years of experience in this domain.

We sell stainless fixings & fastenings like BSF stainless bolts, assorted boxes, vehicle packs, brake/fuel hoses & fittings, wiring, terminals, plus a range of other tools.

If you have any particular requirements, and can’t find what you are looking for on our website, please feel free to give us a call on 02476 470377 or send us an email at sales@wrightsautosupplies.co.uk. We’ll try our best to fulfill your requirements.

Read More: 5 Benefits of Using Self Tapping Screws